Remington 600 Serial Number Dates

You may recall that we reported that Remington is to refit the gun with a new trigger. Apparently not.

It’s not a recall. It’s an “opportunity for any concerned consumers who have the Remington Model 700, Seven, Sportsman 78, 673, 710, 715, 770, 600, 660, XP-100, 721, 722 and 725 rifles with either a Walker trigger mechanism, or a trigger mechanism which utilizes a ‘trigger connector’ to have Remington install a new trigger.” The clarification hails from the Lanier Law firm via PR Newswire [full text after the jump].

Smith Corona typewriter Smith Corona typewriter serial number age list, Smith Corona typewriter model list Smith Corona information. AGUIRRE Y ARANZABAL. (AYA) SERIALIZATION. 1945 to 1994. From 1945 to 1994 AYA had manufactured over. 600,000 shotguns of all models and grades with all serial numbers assigned in chronological order. 1927-1944 year of manufacture date codes, see. 'Spanish Year Of MFG. Date Codes' in this section.

The presser also proclaims that the court settlement announced on Friday was not an admission of guilt. Yes, well, see the official notice to customers above. Seems Remington didn’t get the memo... HOUSTON, Dec.

6, 2014 /PRNewswire/ — On Dec. 5, 2014, papers were filed seeking approval of a proposed settlement of two economic class-action lawsuits of certain Remington bolt-action centerfire firearms that contain either a Walker trigger mechanism, or a trigger mechanism which utilizes a “trigger connector.” The filings triggered multiple news reports that mistakenly conveyed the proposed agreement in significant fashions that require immediate clarification.

• These settlements are not recalls. • These settlements are not any admission that the products are defective or unsafe. • These settlements are an opportunity for any concerned consumers who have the Remington Model 700, Seven, Sportsman 78, 673, 710, 715, 770, 600, 660, XP-100, 721, 722 and 725 rifles with either a Walker trigger mechanism, or a trigger mechanism which utilizes a “trigger connector” to have Remington install a new trigger.

• The benefits under the settlement, including the trigger replacement program, will not be in place until after court approval of the settlement and full notice will go out at that time. This culminates from extensive mediator-supervised negotiations between lawyers for those concerned about the triggers and Remington, who while denying there is any cause for concern, always desires to ensure that its customers are satisfied with Remington products. A joint press release will be issued to better explain details of the proposed settlement. Hundreds of injuries, about two dozen deaths and over $25 million in settlements and jury verdicts paid to victims says that the Remington triggers are bad. Not because of the triggers per se, but because of the “floating” connectors.

This was a defect known as far back as 1946. The designer of the connector (who just died at the age of 101) said that the design was safe but that the manufacturing was not. The people it killed are just as dead.

Remington admitted as far back as 1979 that about 1% of Model 700s had this problem, but did not issue a recall because at the time, Rem had 2 million of them in circulation but only 20,000 were going to be found defective. I have a 700 BDL in.308.

It is a beautiful gun, very accurate and is easy to carry. It spends its life in my gun safe because it fired with out my finger on the trigger one time. Let me say that again ONE TIME. We were standing with some friends after a hunt and I had turned away from my friends to unload my gun. I dumped the magazine out the bottom to empty it, and when I touched the bolt, the gun went off. Fortunately,I know the first two rules of gun safety, treat every gun as if it’s loaded, and don’t point it at anything you don’t want to put a hole in.

This could have had horrible consequences, but it didn’t. However, I have not ever carried that gun since. I didn’t want to sell it for fear of something happening to the person who bought it. It LOOKS good though. My point is it only takes once.that is too many. Back in the mid 80’s when I first heard rumors that Remington 700’s could go off without pulling the trigger, I had a knee jerk “bull$#it” response just like 2hotel9 because I’d hunted with my 700 for years with no problems whatsoever. Then a year or two later as I settled into my deer stand in the freezing pre dawn hours, I became a believer when my 700BDL 30-06 discharged as my right hand lowered the bolt handle with the gun sitting across my lap and nothing near the trigger, the only casualties were a hole in the plywood wall of the deer stand, and my hearing.

I fixed the trigger problem on that 700BDL by trading it for a Ruger 77. Years later I witnessed a near identical discharge of a 700 7mm mag as another hunter prepared to depart camp, his hand was on the bolt and the rifle discharged when he lowered the bolt, luckily the muzzle was pointed in skyward. In the mid 90’s I went through a Remington armorer class that focused mainly on the 870, but briefly covered other Remington products including the 700 and allegations that the fire control system in the 700 was flawed, the Remington factory rep instructor gave us the official Remington response which was that allegations about the fire control system were not true and that the rifle could not be fired unless the trigger was pulled. The Remington instructor seemed like a nice guy so I caught him at the break and told him I had personally witnessed two discharges without the trigger being pulled, he smiled and said, “I know, but I have to follow the lesson plan they give me”.

So 2hotel9, my long winded point is, the trigger/connector issue is real, and Remington has known it is real for a long time. Rule #2 also includes ensuring that your rifle points in a safe direction even if you drop it? And you are always sure of how any theoretical bullets will ricochet off the floor if accidentally discharged?

Or where they will land if accidentally discharged into the air? Panasonic Cf-28 Wifi Card. How safe would you feel about a gun that discharged a cartridge in the chamber every hour on the hour?

Just point it in a safe direction and keep your hearing protection on? Cooper’s rules are designed for guns that only go off when you pull the trigger. Would it be too much to ask for a list of rifles by model, caliber, and serial number range that might be affected by this kind of, maybe, might be something approaching a voluntary sort of recall. While its pick on Remington day, whatever happened to the “new and improved” R51 that was supposed to be back in production back in October? I never saw anything in the press about the R51 so I guess the idiots at Remy are still trying to get that disaster sorted out. Not that anything from Remington is high on my Christmas list anyway. I’m no great fan of Remington managements decisions.

On the other hand, I am mature enough to realize there are no perfect firearms. They are designed, fabricated, and used by humans, and humans are NOT infallible. I have no reason to send my 700 in, it’s over 21 years old and was never identified as being a problem child for others, and hasn’t been for me. If it’s not broke, I’m not going out of my way to fix it. This has been an ongoing issue for years, and when I first read of the difficulties, there was a significant trend in the way I saw the incidences stack up.

It was largely casual gun users who were handling the firearm in a non hunting situation, ie loading or unloading before or after the hunt. When they had a mental attitude that it wasn’t going to be used to kill something. I believe the real issue is they lost the focus it could still be fired if they weren’t paying attention. I see it as the same problem Audi faced with unintentional acceleration – the focus group of uses were mid 50 year old males, and the incidents occurred in a manner that couldn’t eliminate they had simply stomped on the wrong pedal.

The 700 is a firearm whose action must be worked to unload it, and chambering every round into it and then ejecting it is part and parcel of the problem. It must be said that a magazine fed weapon is much less subject to that kind of negligent discharge. It is, to put it bluntly, much more stupid proof. Drop the mag, retract and lock back the bolt, clear, especially with the AR15, which is the watershed example of intrinsically safe modern self loaders. The 700 isn’t, and neither are a lot of other manually loaded guns, which should give pause to those who deride them as “dangerous.” They are quite apparently much less so, it’s the 700 getting the press, not the AR15 makers.

Quite the contrast to how some would like to paint them, but that goes to traditionalists supporting antigunner goals more than the 2 Amendment. Elmer, I am talking about you. Learn how to handle your old antique designs which you revere so highly, or suffer the consequences.

You can’t blame the makers for faulty handling of a firearm. The unloading sequence you describe is necessary on only the 700 ADL, which has a blind magazine.

The blind magazine was yet another cost-cutting tactic by Remington. On other bolt-action rifles, you need not cycle the bolt to unload it, much less chambering a round to get it onto the extractor/ejector. On the Mauser, Springfield 1903/A3, Winchester 70, Remington Model 30, Remington Model 30 Express, Remington Model 798, etc – you can drop the magazine floorplate.

Out comes all the unchambered rounds. Oh, but the floorplate and floorplate latch – those cost money, so Remington wanted to get rid of them. On a claw-extractor rifle, if you want to cycle the action, the claw extractor on these three actions will allow you to get a round out of the magazine and under the extractor well before the round is fully chambered – you can short-stroke the bolt to unload a claw-extractor bolt action, since the case rim will slide up the bolt face and under the claw on its way out of the magazine. Moreover, with the Model 70-style three position safety, the firing pin is rendered frozen in the bolt while you’re operating the bolt. You could chamber/unchamber rounds all day long on a Model 70 with a three-position safety and it won’t fire. The safety on the Remington 700 simply cams the sear off the connector. It doesn’t do anything to immobilize the firing pin in the bolt.

The problem with chambering/unchambering rounds to unload them on the Rem700 is that their extractor is a stupid little piece of spring steel riveted into the bolt nose. You have to chamber a round (or come very, very close to closing the bolt completely) to get the extractor on an original 700 to ride over the case head rim. Need I say point out that the extractor on a Rem700 is yet another cost-cutting measure? It spawned a whole new industry for gunsmiths – installing Sako and AR-15 style extractors onto Remington 700 bolts for owners who got tired of their extractor clip breaking out of the bolt. Well, if this isn’t a major PITA, I don’t know what is. (Other than an AD, mind you.) I’ve got TWO 700s, and both of them were made in the 1990s before Big Green started to smell bad. Both of their triggers are factory-stock, and still have the factory epoxy on the adjustment screws.

I’ve shot many hundreds of rounds through each of them without issue, and I am far from excited at the prospect of shipping them for several months to a manufacturer I don’t entirely trust any longer, to install a ‘new’ trigger group that was designed (unless I’m mistaken) by one of the plaintiffs in this lawsuit. I think I’ll stick with the triggers I know and trust, but I could be persuaded otherwise. It’s too bad that this once great American company has been run into the ground. I know the trigger issue dates well before the Cerberus era, but it’s gotten exponentially worse. I sold my 2011 870 as a “gunsmith special” because they somehow found a way to make a pump gun unreliable.

That and I could bathe it in CLP and it would still rust. My father has a couple of Remington’s that he bought in the 70’s (an 870 wingmaster and a 760 woodsmaster) and they are both buttery smooth actions and 100% reliable, they’re furniture and metal still looks beautiful 40 years later. OK, I’ve read enough about “conspiracies” and “agendas” on this issue that I really have to explain with pictures what is going on. Here’s a copy of the original patent filing for the Walker Fire Control System: Go to the second page of this document. Look at Figure 5.

I’m now going to explain to people exactly what is going on and why. The trigger that you put your finger on is labeled as “40” in these drawings. The “connector” that I’ve been talking about (seemingly to no avail) is “39.” The sear is 16. When the sear’s step 38 is resting on top of the connector’s edge 39, (look at the top & left edge of 39 on top of the trigger), the sear remains in the high position, the cocking piece of the bolt is held to the rear, meaning the firing pin is held back off the cartridge. When 39 is moved to the right (in Fig 5, or forward in the rifle), the connector (39) is pushed out from under the step on the sear (38) and the sear is pushed out of the way of the cocking piece and the firing pin slams forward on to the primer. OK, let’s pick up the applicable language from the patent filing: “Trigger spring 42 seats against an adjustable screw 43 and bears on the forward face of the connector resiliently urging the connector into engagement with the trigger and through the connector, resiliently urging the upper end of the trigger rearwardly.” I didn’t write that folks, that’s how Remington wrote the patent app. Right there is the nut of the problem.

If the spring pressure from 42 is insufficient (eg, someone has adjusted trigger pull weight screw (43) to too light a weight), and there is any sort of gunk, crud, or other impediment to the connector (39) moving rearwards with the trigger (40) while the safety is on, your trigger(40) is in the reset position, but the connector is still forward (ie, off the front face of the trigger). Now there is nothing under the sear step 38! At this point, if your safety is on and you release the safety (ie, you cam the safety cam 36 down and forward), the sear is pushed down as the cocking piece is pulled forward by the firing pin spring, and the rifle fires. It is as if the trigger were already pulled when you pushed the safety off. That’s the important point here: When the connector doesn’t move rearwards with the trigger (40) on trigger reset, you haven’t reset the trigger. The trigger is already effectively pulled.

OK, let’s take another case: You’re pushing the bolt forward on a live round – fast. The connector is stuck in the forward position. You slap the bolt closed and the cocking piece is only barely retarded by the sear; the rifle can fire. There is no conspiracy, there is no agenda. The issue is that the trigger has a faulty design. The connector should never have been allowed to float on the front of the trigger – it should always have been an integral part of the trigger.

Your explanation is EXACTLY right. My experience is that too many people who do not know what they are doing have tried to “adjust” their Remington triggers. In doing so they have created the perfect scenario for a ND. Namely, the “poundage” adjustment screw has been adjusted so light (. It’s not a Government-mandated recall because the Consumer Product Safety Commission is forbidden by law to enforce safety standards for guns. The gun lobby got that enacted into law decades ago. This Remington 700 problem has been widely known since at least 2010.

See “It’s Remington’s third recall for “fires without trigger being pulled” problems. See “The 887 and 710 have also had defects resulting in accidental discharges, for different reasons than the 700. This is a huge embarassment for Remington. Colt and Glock have had recalls, but nothing this bad.

I love apologists. ISIS hasn’t cut my head off so they must be great guys.

We should get together for a beer or two. I haven’ t seen the problem, so it can’t exist. Uzi’s are fantastic weapons, let’s give one to a nine-year old girl. Two dozen people have been killed by this manufacturing problem. More have been wounded.

Do you need someone in your immediate family in a casket before you’ll admit the chance of a problem? I support the right to keep and bear, but the more I see junk like this, the more I think you should have to pass an IQ test before you can buy, or be issued, a weapon. Ah, but you see, you’re thinking like a gun owner and shooter, not a gun maker. And more specifically, you’re not thinking like a gun maker that’s run by financial types, ie, MBA’s and finance majors. I’ve ranted and fulminated here at TTAG about the cost (and corner) cutting by Remington in a quest for higher margins and lower COGS. This isn’t a new issue.

This issue goes clear back to the 1950’s with Remington. With the Remington 700, the cost-cutting campaigns for cheap heat-treating show up in at least two places in the action: 1. The three-piece bolt that is soldered together. Only the front end of the bolt, which includes the lugs, is hardened. The hardened frontpiece of the bolt is soldered onto the bolt body, and then the handle is soldered onto the body at the rear. This allows Remington to heat treat all the frontpieces at once in an oven, quenching and tempering them as necessary to gain the required strength in the bolt lugs and the lip of the bolt face (part of Remington’s “three rings of steel” ad campaign). The connector in the trigger.

Trigger mating surfaces have to be hardened pretty darn hard, lest they wear and (worse) feel “mushy” and kinda like you’re dragging a garden rake through cold peanut butter as you pull the trigger. There are two ways trigger components are hardened: – full through, then tempered back. This allows you plenty of depth on which you can polish out the trigger mating surfaces. – case hardening (where there is only a hard outer shell on the steel in the trigger, sear and other mating surfaces). This is done on AR-15 factory triggers. You can’t polish an AR trigger hardly at all before you break through the case layer, and then you might as well throw away the trigger and buy a real trigger.

Most older-school guns would harden through and temper (or “draw back” in English gunsmithing terminology) back the hardness and there you’d have your trigger pieces. Then they have to have fixtures that allow them to grind and polish the angles and steps on the mating pieces to a nice finish, because even if the mating surfaces are hardened, if there is any machining marks or grind marks on the mating surfaces, you will feel these as you pull the trigger – when you feel grit and crunching on the trigger pull, that’s the machined marks or grinding marks that haven’t been polished out riding over each other. Remington looked at the situation and said “Golly, if we could do with the one or two pieces in the trigger what we did with the frontpiece of the bolt we could make nice triggers inexpensively!” So what they sought was a small piece of steel that could be made in a very easily dealt with shape that would be the piece hardened and polished. The connector was created.

The connector is hardened, but the main trigger bar isn’t. The connector is polished and ground nicely, all by itself, so that there’s no need to polish a hardened surface on the trigger bar. This is a brilliant solution to the problem of triggers costing money and skilled labor. It gets you a nice, crisp trigger pull at a bargain basement price.

Sadly, it also introduces a couple of very bad failure modes when the connector comes apart from the trigger bar. I have a (1980’s?

Not sure) bolt action, 3 round Magazine, Remington Model 788, 30-30 caliber, serial 033889. Is this weapon a part of the serious trigger safety problem I see aired on TV on 60 Minutes 2-19-2017? I have hunted with this weapon very little over the years 1980-2015, but my 34 year old son has gone hunting with the weapon and has it stored at his home in a locked gun cabinet.

I worry now after seeing the 60 Minutes program identifying trigger defects that have lead to deaths involving 700 series Remington weapons. Should I get a gun smith to inspect the weapon? — Anyone please advise.

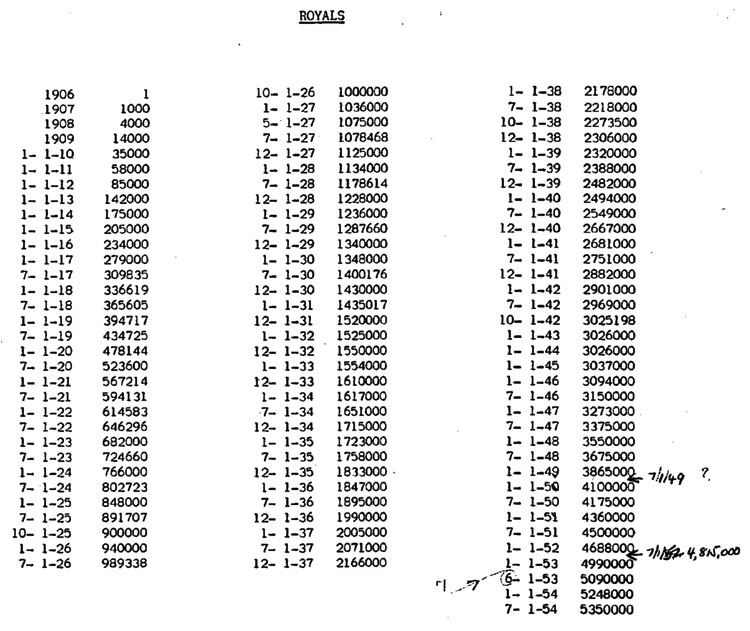

Remington Model 600 Type Place of origin United States Production history Designer Manufacturer Produced 1964–1967 (original) 1971–1980 (Model 600 Mohawk) No. built 94,086 Variants see Specifications Weight 5.5 lb (2.5 kg) Length 37.25 in (94.6 cm) length 18.5 in (47 cm) Barrels Round with ventilated nylon rib Sights Blade ramp font, fully adjustable rear. Remington Arms Model 600 was a push-feed produced by from 1964–1968. While it is commonly believed that production ended in 1967, according to Remington representatives records indicate that it actually ended in 1968. This Model was the precursor to the Model 660 (manufactured 1968–1971); the Model Mohawk 600 (manufactured 1972–1979); and the (manufactured 2003–2004). Contents • • • • • • Overview [ ] The Model 600 was designed to be a guide rifle.

Its most noticeable feature was the vent rib barrel. There were approximately 94,086 rifles produced in the available calibers of:,,,,,,,. The rarest is the one chambered in; only 227 were produced—most in the final year of production. [ ] Before it was officially added to the line, you could order a Model 600 out of the custom gun shop in.

At least one Model 600 in came out of the Remington Custom Shop in 1966. A successor model, the Remington Mohawk 600 ('72-'79) available in.222,.243 and.308 comprised total production of only 142 with a Mannlicher-style stock.

But the rarest Original Model 600 was and remains the.223. Variants [ ] There were several variations in the original production line and they were the: (1) 600 Magnum Carbine, (2) 75th Anniversary Montana Statehood, & (3) 100th Anniversary Montana Territory.

Remington Model 600 Magnum [ ] Same as the Model 600 except that it was available in and. Also featured a laminated walnut stock, recoil pad and sling.

Remington Model 600 Mohawk [ ] Same specs as the Model 600 except featuring an 18.5 in (47 cm) barrel with no rib. It was a promotional model produced from 1971-1980. Popularity [ ] While loved by the majority of its owners, the death knell of the original Model 600 and its descendants were its looks; it was largely despised by critics, even though it shot exceptionally well. The original barrel length of 18.5 inches resulted in more felt muzzle blast, especially in the. This actuality and perception led to failure of the cartridge in the later guns of different models too.

Remington finally abandoned the cartridge in the late 1970s, until resurrected in 2003 with the Model 673. The 600 series received attention through the writings of, who used the model 600 as the basis for his 'Scout I' and 'Super Scout'. References [ ].